When it comes to blades, steel quality is everything when it comes to selecting a good one. Knives and any other blades made of Damascus steel are always in our wheelhouse. For good reason too. Primarily because the best part is that knives made from this fabled steel maintain their edge and their value for many years past their manufacturing date. While it is not the number one strongest metal used to forge blades, Damascus steel is tremendously well recognized for its beauty and flexibility. Not only that, but it comes in many reasonably budget friendly models. Today the steel is used in a bevy of pocket knives, hunting knives, and survival knives. There’s something for nearly every sportsman and woman out there.

There is a lot to be said for these knives and other tools made from this process, but while modern Damascus steel is made from the same techniques, it is not quite the same as the original metal. Let’s look at the name, the origins, and the process of making one of our favorite type of blades.

Damascus Steel in a Nutshell

Getty Images: max grpo

As far back as the Crusades and even longer, to the time of Alexander the Great, true Damascus steel was made by Middle Eastern blacksmiths and coveted for its beauty and strength. As the New York Times reported many years ago: “Crusaders reached the Middle East, beginning in the 11th century. They discovered that swords of this metal could split a feather in midair yet retain their edge through many a battle with the Saracens. The swords were easily recognized by a characteristic watery or ”damask” pattern on their blades.”

At some point, these amazing and industrial artisans began importing ingots of a new type of steel called “Wootz” steel from an area in Southern India. This new brand of material was instrumental in creating new and more advanced swords and knives that were exceptionally lightweight and strong. Damascus steel was found to be very rich in carbon, especially compared to other weapons of the day making it quite formidable. In fact, it held up exceptionally well compared to other materials of the day, which earned it quite the reputation, and made it famous. Weapons of the day and other items made from Wootz were extremely popular around the third and fourth century, particularly in the city of Damascus in what we now call Syria. Unfortunately, Wootz steel (as it was called) does not exist today as we know it, but modern forging techniques using high-carbon steel, together with a pattern-welding process can approximate the historic original Damascus steel today.

Making Today’s Damascus Steel

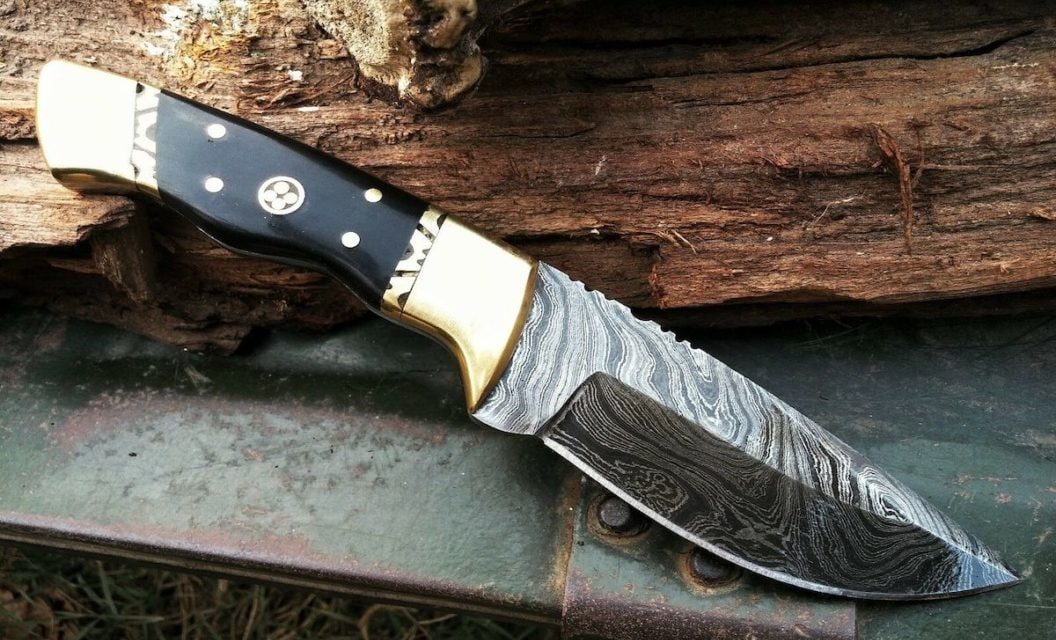

Richly imbued with beautiful aesthetics and high performance, Damascus steel knives are some of the most popular tools we use as sportsmen. The withering design alone is enough to garner a response, but it is the usefulness of these knives that make them so well received. They’re light, offer excellent durability, and hold an edge well. All desired qualities for any blade you are going to use for outdoor activities.

Today’s Damascus steel is made by a process of layering multiple parts of iron and steel to “pattern weld” and then hammer the product at a high heat to form a welded bond. Forge welding many layers produces the watery effect pattern that is very characteristic of Damascus steel. Although other patterns are possible as well.

It is important to know that true pattern welded Damascus steel bears this watery pattern throughout the implement, while some of the knives you may see for sale have been etched to make them appear to be Damascus steel, but this etching will wear away over time. It is usually obvious which ones are built using modern Damascus steel techniques in the price. Even with modern knifemaking tools, making blades of this type is an art. It requires an extensive forging process at high temperatures and using skilled hands to get it right. Knifemaking is an art form, and some of the best bladesmiths rightfully charge top dollar for their work.

Why We Love Damascus Steel Blades

Getty Images: ulkan

The beauty of a knife made by the Damascus steel process may be the best thing about them, but when you stop to consider their usefulness, you’ll be glad that you spent your hard-earned money on one. There’s a marked difference between one of these blades and the cheap carbon steel blades full of impurities that anyone can buy from a big box store. You’ll notice it instantly in both the cutting ability and the balance and feel of the blade. You don’t need to be a history buff to appreciate them either. Everyone from collectors to proper everyday users love the look, the quality, and the long-lasting effectiveness of a well-built Damascus blade.

It’s said that no two Damascus blades are quite the same due to the manufacturing or heat treatment process and are valuable just for the artistic quality they possess. As a hunting knife, they are ideal just for their resilience and toughness. The versatility that they possess due to their edge retention may have no match. It is said that if you come across a Damascus steel knife that has been made with the pattern welding process, it is legitimate even if it has acid etching. As Frontier Blades says, “First and foremost, if the Damascus knife highlights highly elaborate, detailed, and unnatural designs (not the general watery, folded, ladder, wavy, twist, raindrop, or feather patterns) it is most likely not legitimate.”

We know many are on the fence when they see one of these blades for sale because of the high price tag. However, in case you were wondering, as with any good piece of gear, you get what you pay for with Damascus knives. Over the centuries they have earned their reputation, and their high price points fully.

Please check out my book “The Hunter’s Way” from HarperCollins. Be sure to follow my webpage, or on Facebook and YouTube.

NEXT: BEST CAMO FACE PAINT OPTIONS FOR HUNTERS OF ALL KINDS

The post Damascus Steel: The Properties That Make This Metal Great for Knives appeared first on Wide Open Spaces.